Boiler House Upgrades

Project Details

Custom Steam was asked by a large multinational dairy manufacturer to help them with issues that they had been working with for over 10 years. Poor water quality, low pressure causing softener issues creating hard water, out dated controls on their feedwater system and outdated engineering drawings for their utilities infrastructure led to frustration and operational inefficiencies. The engineering team of Custom Steam together with their certified energy managers assisted the client with establishing a base line for current energy, water and boiler efficiencies using US dept of energy on line modelling software. From the 4 days on site mapping and tracing lines and current P and ID Custom Steam were able to produce updated drawings for steam, condensate, city water and boiler infrastructure.

The 20 page audit report identified short and longer terms opportunities for technology upgrades, water and energy reduction and processes which were causing operational inefficiencies. This report gave a two year plan on identified projects. During several meetings and Teams calls we identified the projects with the quickest payback and efficiency gains. Custom Steam have started work on four of the seventeen projects started and assisted the client with rebates from the gas company.

Technical highlights

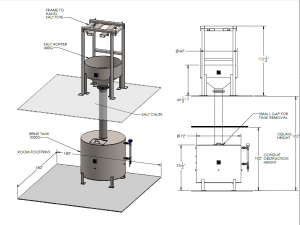

• Bulk Salt system to minimize salt handling and assist with increased softener loading

• Upgraded controls on DA and condensate return system using Eurotherm Nanodac logger and controller.

• New 300HP boiler installation providing improved efficiency and lead lag system

• New softener and polisher to reduce hardness in boilers and better delivery to processes