Clean Steam Generator

Project Details

Custom Steam was approached by a major building automation and FM company to assist with issues with clean steam for their sterilizer and humidification systems.

The current units were undersized and had poor control design leading to varying fluctuations in pressure to the clean systems within the hospital.

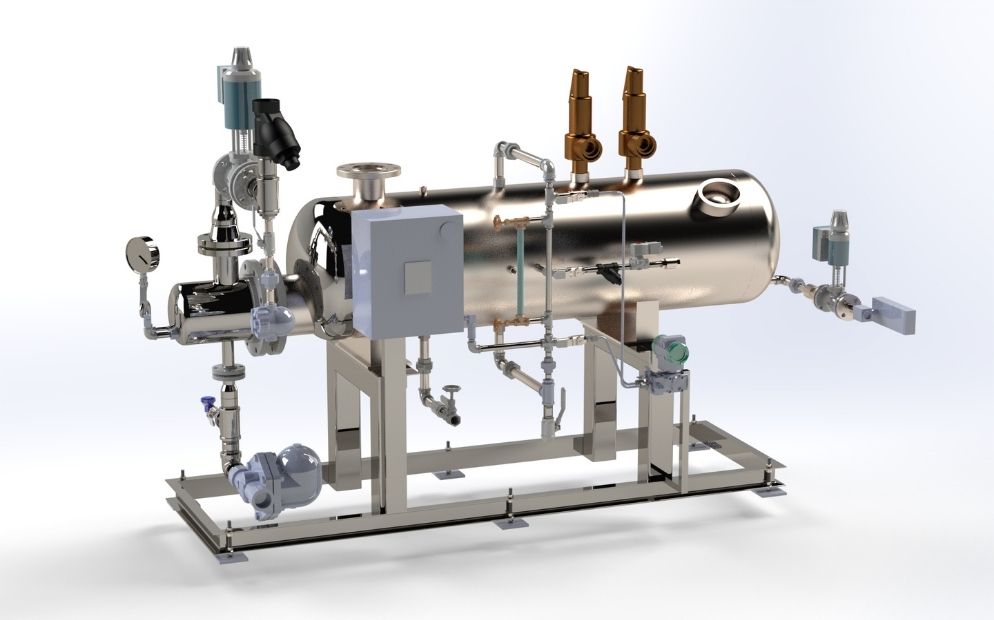

Manufactured at our ASME shop in Cambridge we used 316L stainless steel for the construction of the shell and bundle and the design included

We worked with the on site FM teams and the contractor to design and manufacture a unit that exceeded their expectations.

Technical highlights

• Integral steam separation for dry clean steam

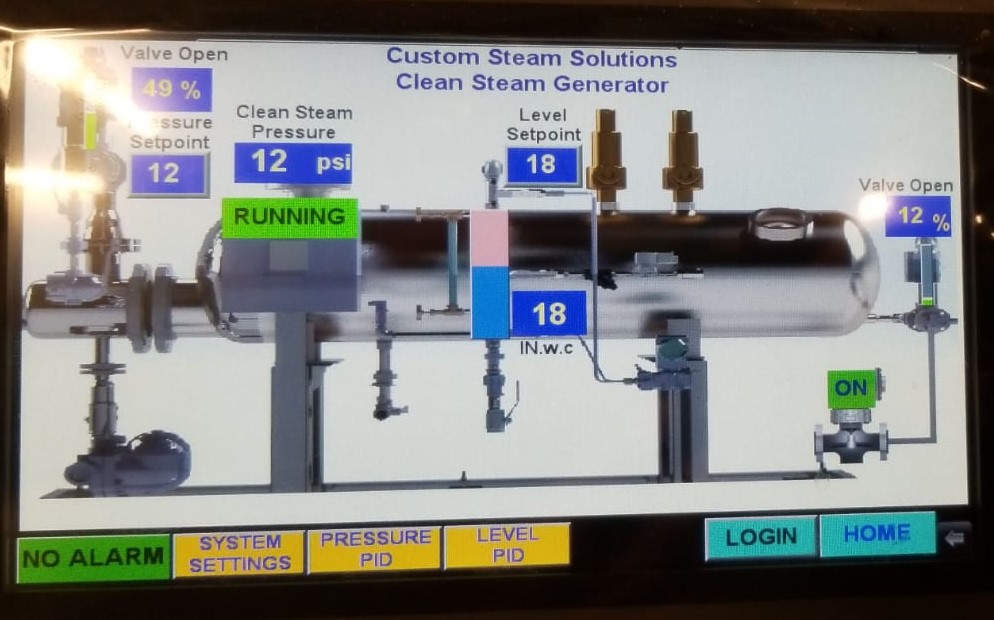

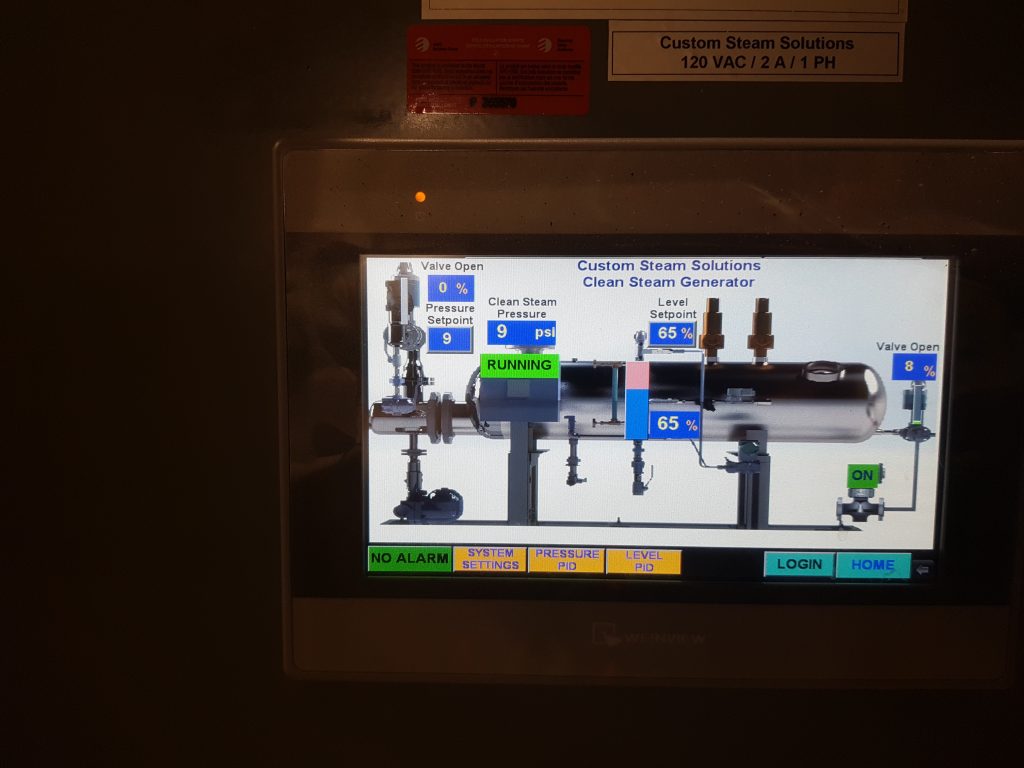

• Electric control valves with Smart actuators

• Proportional modulation for make up water feed

• Pre heating for energy reductio, reduced carbon footprint and oxygen content

• Fully packaged and assembled in our facility

• Factory acceptance test performed

• Produced 20% more steam than competitors equivalent sized unit

• ASME U stamp, CRN for Ontario and CSA approved panel

• Eurotherm Nanodac with HMI for control of pressure, level and conductivity.

• Bacnet integrated MSTP or Ethernet IP

• Manufactured 100% in Canada