Heat Cool Skid

Project Details

Custom steam were invited to bid for a heating cooling application for a new expansion to a pharmaceutical plant in Ontario. Meeting time deadlines we prepared the functional design with the client, met site requirements with limited access and ensured existing mechanical room area was waterproofed and contingency for flooding was scoped in since manufacturing equipment was the next floor down. This would stop production.

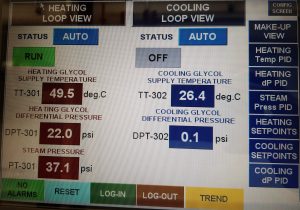

Using a modular design concept in our facility in Cambridge we designed and built two skids, one heating and cooling for the process of heating and cooling water and glycol to the tank farm. Accurate temperature control was required to protect the product in the mixing tanks. Custom Steam solutions offered 3D models, P&ID and installation services for mechanical and controls.

Technical highlights

• Flooded Megaheat shell and tube 316ss constructed in our shop in Cambridge

• Armstrong drives for heating & cooling loops to provide variable circuits to save energy

• Armstrong plate and frame cooling heat exchanger

• Allen Bradley Control Logix Plc Panel with Panelview HMI

• 316 stainless steel piping

• Factory acceptance test

• Full documentation to meet requirements of Pharmaceutical industry